A Closer Look at the Bandsaw

West Yorkshire Steel are happy to offer a number of different steel processing services – the options that we have mean that we can deliver a range of different products to our customers just as they need them! We decided, however, that it would be good to look into some of the toys that we have on site that help us to cut and shape our steel, starting with the bandsaw.

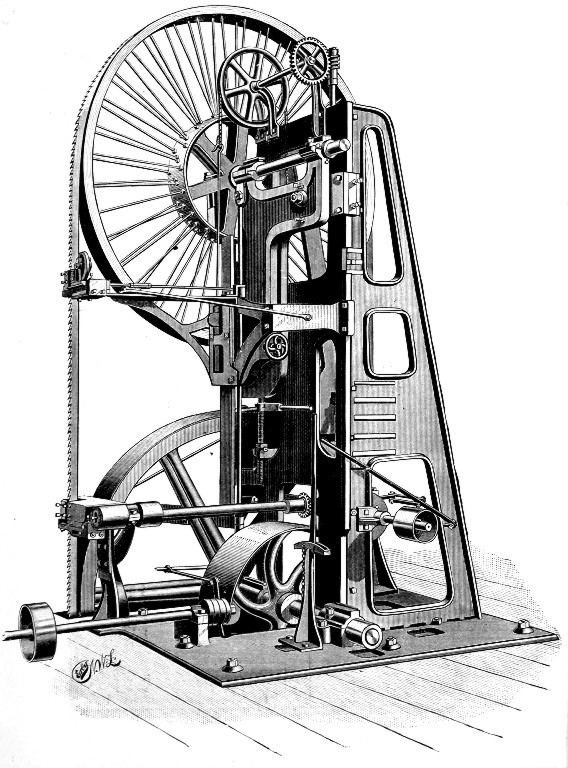

If you’re not sure what a bandsaw is, then imagine an extremely long saw blade and join the two ends together to make a loop. The looped blade is then mounted vertically between two wheels that controls the speed the blade travels at, and the cutting edge is one of the vertical edges, where the blade runs straight from top to bottom.

The major benefit of the bandsaw is that the cutting edge only runs in one direction, meaning that neither the blade or the material being cut has to cope with stresses and strains in different or competing directions, like a circular cutting blade would give. Depending on the length of the blade, it can also limit the amount of heat built up through friction as the blade’s travel time allows it the temperature to remain more steady.

Although chiefly a woodworking tool, technological developments have allowed blades to be made stronger, more reliable and more resilient to the pressures that cutting causes. Today, we can tailor equipment to perform any number of jobs, including allowing bandsaws to cut any number of metals – which is great news for our customers!

West Yorkshire Steel supply rectangular cut block and plate as cold sawn, meaning that it can be supplied close to your required finished dimensions, while round bar can be cold sawn up to 1000mm in diameter – and as always, we can supply nationwide across the UK!

Take a look at this page for 27 Fun DIY Bandsaw Projects You Can Start Today – https://sawshub.com/fun-band-saw-projects/

Photo Credit: By John Henry Walker (1831-1899) [Public domain], via Wikimedia Commons