Fighting coronavirus needs the right equipment – and materials!

Those people who know West Yorkshire Steel and those who read our blog will be familiar with our belief that there’s always a material that’s perfectly suited to the job at hand – and it’s surprising how often that material is steel! We genuinely find it a fascinating material and love that a little tweak in the treatment or chemical composition of the material can bring such incredibly different results.

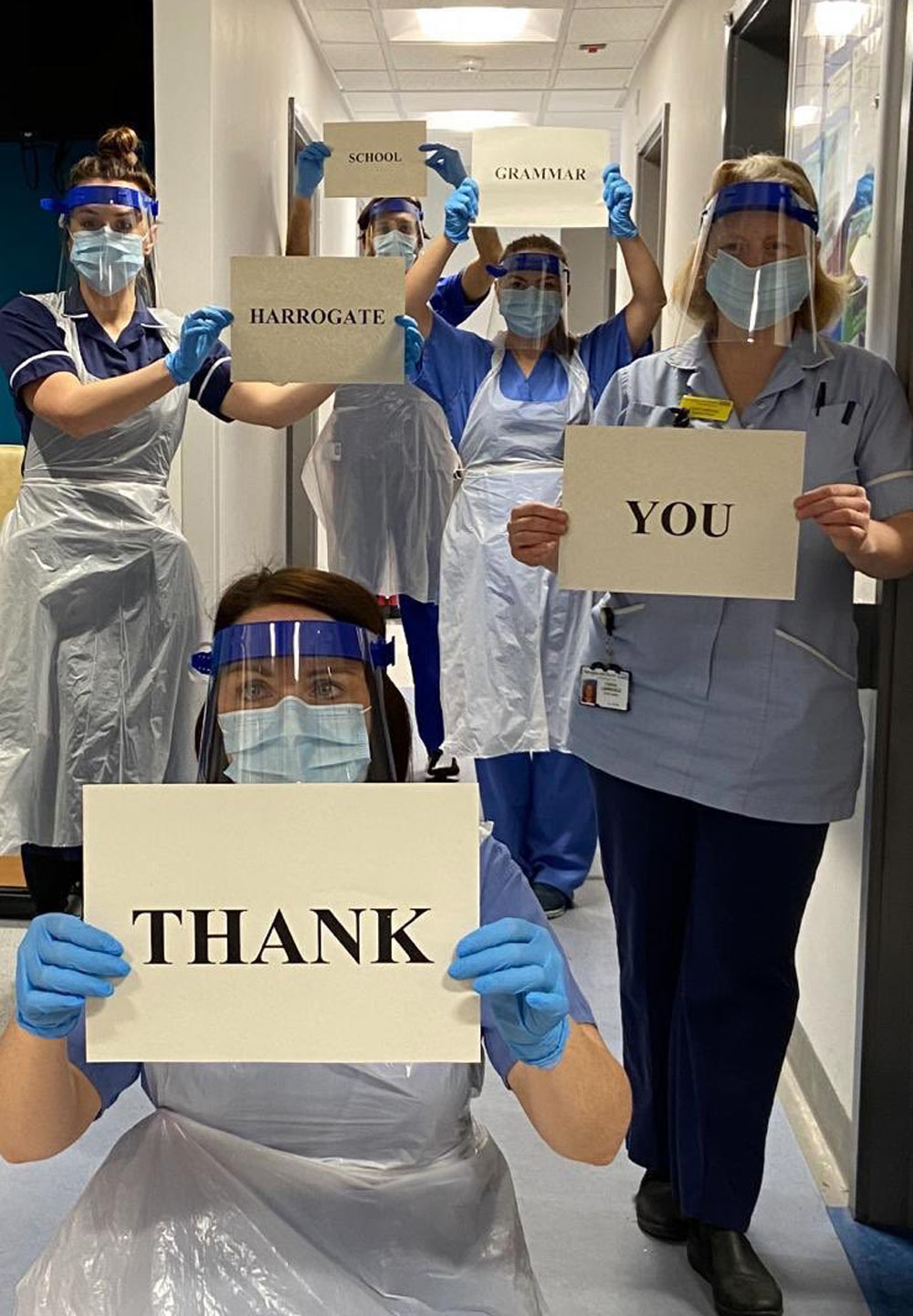

We also know, however, that sometimes there are other materials that are more ideally suited, and a few weeks ago we found out that Harrogate Grammar School was turning its Design Department into a studio to create Personal Protective Equipment to help with the fight against the current pandemic.

We’ve always been very proud of this particular part of the world, not only for the history and the fact that steel from Yorkshire is famous on a global scale, but also because of the people and community that are here. When we heard about Harrogate Grammar School’s plans, we also found out that it was being powered by some of the pupils’ parents who were furloughed, some ex-engineers were offering to help out too and we decided that we’d offer what we could to help a genuinely inspiring project.

The school’s Design Department has been making visors with the aim of supplying them to the NHS and we quickly realised that donating steel for the cause probably wouldn’t be very useful. Instead, we spoke to Jo Oates over at the school who told us specifically that they urgently needed white polypropylene sheeting. We gladly donated sheets of what they needed at half a millimetre thickness, which we hope will keep them moving for a while! Obviously we can send over more should it be needed.

One of the things that’s really impressed us – not just that this school is really trying to make a difference – but that the product has been highly professional. The use of 2D laser cutting to create the templates isn’t what many people would assume a school’s Design & Technology department would be doing, but it shows a remarkable commitment to consistent, professional results. We’re guessing that some of our older readers will be surprised at the capabilities of schools these days, just as we were!

At the other end of the scale, we also work with and supply a number of engineers who work in the pharmaceutical, medical and food industries, so it’s nice to know that our more usual steel products may also be helping in the fight against coronavirus. The steel supplied is most often used for tiny or intricate machine parts for equipment, which is frequently the most suitable material for the job.

We’re really happy to have a little part of a project that’s not only saving lives, but also giving young people a start in the real world applications of engineering, which we feel is never a bad thing! We’re also happy to admit that sometimes, just sometimes, plastic and not steel is the perfect tool for the job!