Tool Steel Is A Complicated Business – But What’s So Special About It?

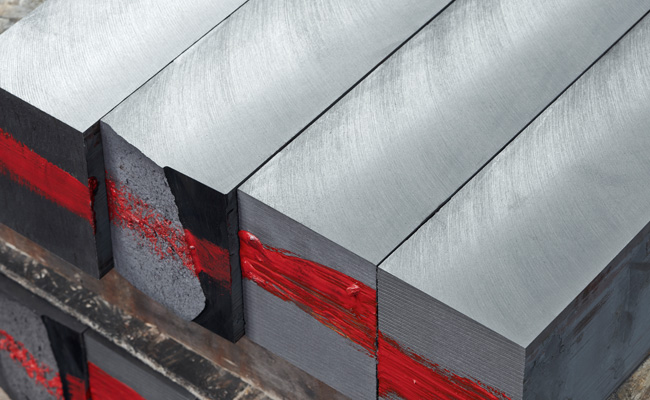

For steel aficionados, tool steel is a familiar but spectacular marvel – a technological and scientific exercise that produces some of the most impressive steel grades available! If you’re not familiar with tool steel, as you’d expect, it’s a type of steel that’s used in tools and machinery – everything from blades, cutting dies, presses and sharpeners.

It’s no surprise that steel in various types of machinery goes through an awful lot of strain and stress. Tool steels must be able to resist wear or deformation, retain their hardness or resistance to abrasion and corrosion or be able to withstand shock or forces that may shatter lesser steels. There are various types of tool steel; including hot work, cold work, high-speed, and shock-resistant and their composition and hardening capabilities vary.

If your tool steel needs to retain its hardness and strength at increased temperatures, then there are a number of hot-work steels available. These are designed to retain good hardness and toughness under heat stress without losing too much resistance to wear by having a lower-end carbon amount. There are a number of tungsten, chromium and molybdenum based steels that provide much better control under high temperature.

At the opposite end of the scale, some steels become brittle when exposed to low temperatures, so the cold-work group of tool steels are needed. Rather than water-hardened, they tend to be oil or air-hardened and have higher carbon content. Increasing the number of alloyed materials also means that steels can be made harder and quenched less severely, reducing the risk that sudden deviations can leave cracks or imperfections in the final product.

High-speed steel grades can often come into constant contact with other materials without losing its temper or hardness. High-speed steels resist grinding and other forms of deformation, which allow them to cut faster, at higher speeds and for longer than other less suitable types of steel, in turn making them more efficient. Thanks to a number of different make ups, there are a few different types of high-speed steel, including cobalt, molybdenum and tungsten steels, which have variations on their capabilities to deal with friction and abrasion at increased speeds.

Shock-resistant steels are alloys that use a number of carefully controlled components to give good wear resistance with high-impact toughness. Sudden impacts can cause weaknesses in steel to fracture or cleave, but the formation and use of chromium, tungsten, molybdenum and manganese helps to keep the integrity of the steel intact.

Special purpose steels are the other group that aren’t covered by particular uses, which include very tough steels, such as L-type steels or P-type steels that are used for plastic moulding.

Although we think that there’s something special about almost every type of steel, you have to tip your hat to the hard working, ever-ready workhorses of the steel world, who raise the bar and allow us to achieve much more with the clever application of a little science.